our machines building your dreams

Welcome to ABT Metals: Your Precision Metal Stamping Solutions

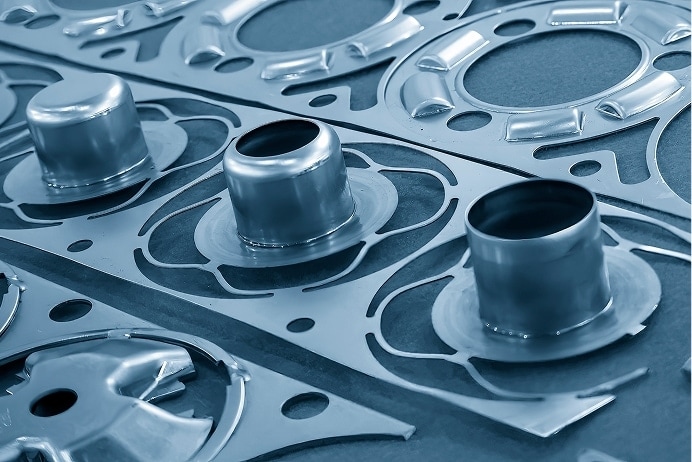

Metal Stamping is a crucial process that allows metal manufacturers to efficiently and precisely form metals into the desired shapes. At ABT Metals, we pride ourselves on offering reliable and efficient precision metal stamping services. Our expertise in metal stamping caters to a wide range of industries, including aerospace and automotive, where precise metal parts are essential.

Materials and Products

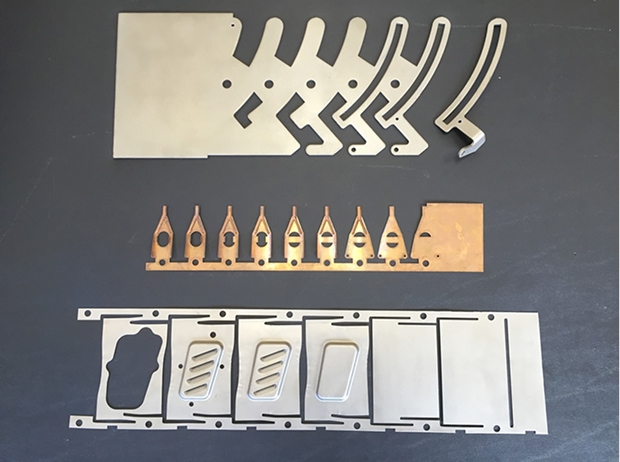

We work with a variety of metals, including aluminum, stainless steel, and carbon steel, to create a range of products, including enclosures, cups, cans, shells, and decorative stampings.

Metal Stamping in Steel

Steel is the go-to material for metal stamping when strength is a priority and weight and corrosion are not major concerns. Our use of coil-fed steel and steel blanks allows for extra adaptability.

Metal Stamping in Aluminum

Aluminum stamping offers a multitude of advantages, making it one of the top choices for metal stamping. It’s easy to work with, lightweight, and corrosion-resistant.

Sheet Metal Stamping Capabilities

Our metal stamping capabilities cover a wide range of sheet metal gauges, from heavy gauge metal stamping to thinner metals used in automobile and appliance sectors.

Industries We Serve with Precision Metal Stamping Solutions

Our sheet metal stamping services cater to a wide range of industries requiring tight tolerances, durability, and high production efficiency. As a precision metal stamping manufacturer, we provide solutions for:

- Aerospace & Defense – High-strength, lightweight metal components built for extreme conditions.

- Automotive & Transportation – Precision-stamped parts for fuel systems, chassis, and interior components.

- Medical & Healthcare – Surgical instruments, medical enclosures, and critical stamped components.

- Electronics & Telecommunications – Custom metal shielding, housings, and heat sinks.

- Renewable Energy – Stamped components for solar panel frames, battery enclosures, and wind turbines.

- Industrial & Heavy Equipment – Heavy-duty stamped metal parts for large-scale machinery and construction.

As one of the leading stamped metal parts manufacturers, we customize our stamping processes to meet industry-specific demands, ensuring reliability and longevity in every component.

Advantages and Disadvantages of Sheet Metal Stamping

Our metal stamping process offers excellent properties such as strength and lightness, with a variety of finishing capabilities. While simple to operate, it may require a higher initial investment for short-term production.

Mastering the Art of Metal Stamping: Our Techniques

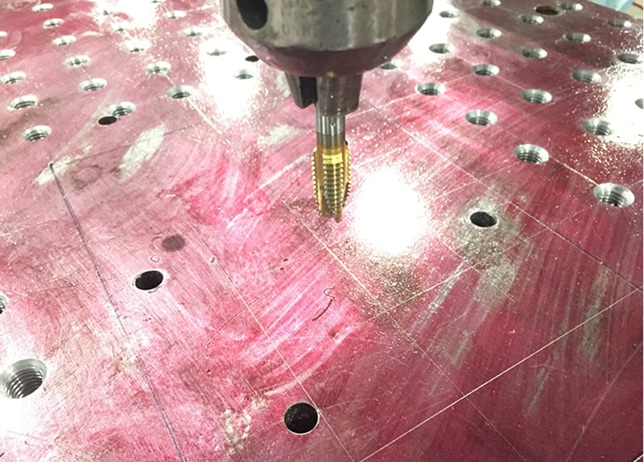

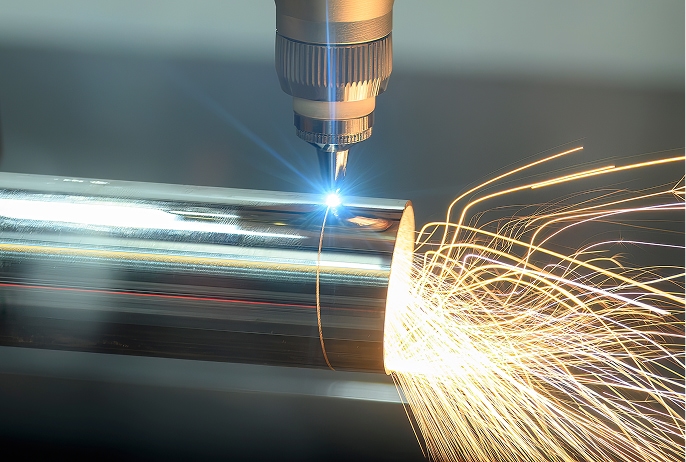

ABT Metals utilizes advanced stamping technologies to manufacture complex and high-strength metal components. Our precision metal stamping services include:

Press Brake Stamping

Using high-tonnage press brakes, we bend, shape, and form sheet metal with extreme accuracy. This method is essential for producing angled components, enclosures, and brackets used across various industries.

Heavy Gauge Metal Stamping

Heavy gauge stamping is designed for thicker materials, typically ranging from 24-gauge to 20-gauge sheets. This process demands higher-tonnage presses to form structurally reinforced metal components. Whether it’s stainless steel, brass, or aluminum, our heavy gauge stamping ensures strength, durability, and precision for high-load applications.

Progressive Die Stamping & Custom Tooling

Our progressive die stamping allows for high-speed, multi-step part production, reducing labor costs while maintaining precision and efficiency. With custom tooling capabilities, we deliver tailor-made stamping solutions for unique project requirements.

Our Stamping Process and Equipment

Our metal stamping process involves transforming and reshaping sheet metal using cold-forming techniques, enhancing production speed and uniformity. Our versatile stamping equipment enables a wide range of capabilities, ensuring precision and accuracy in every product.

Quality You Can See, Precision You Can Trust

At ABT Metals Manufacturing, quality isn’t an afterthought—it’s built into every step of our custom metal stamping manufacturing process.

- ISO 9001:2015 Certified – Every stamped part is produced under strict quality control measures, ensuring consistency and compliance with industry standards.

- Advanced CNC & CAD Technology – We use computer numerically controlled (CNC) systems and computer-aided design (CAD) software to maintain repeatability and accuracy across all production runs.

- State-of-the-Art Stamping Equipment – Our facility is equipped with high-tonnage presses, automated feeders, and precision cutting tools, ensuring high efficiency in small-batch and large-scale production.

- Material & Process Inspections – From raw material selection to final inspections, our quality control team ensures every stamped component meets or exceeds specifications before it leaves our facility.

As an ISO-certified metal stamping manufacturer, we don’t just meet industry standards—we set them.

Your Trusted Metal Stamping Partner

At ABT Metals, we prioritize delivering high-quality and precise metal stampings. With cutting-edge technology and a dedicated team, we guarantee superior results for your metal stamping requirements.

Request a Quote for Precision Metal Stamping Services

Looking for a trusted precision metal stamping manufacturer that delivers quality, accuracy, and efficiency? ABT Metals Manufacturing has the expertise, equipment, and ISO-certified processes to bring your custom-stamped metal parts to life. Request a quote today! Let’s build something exceptional—together.

Additional Services We Offer

At ABT Metals Manufacturing, we take pride in offering the highest quality metal fabrication services in North Carolina.

Give us a call or fill out the form and our team will be in touch as soon as possible.

*marks a required field

Quick Contact

"*" indicates required fields