our machines building your dreams

Precision Metal Laser Cutting Services

You need a reliable and precise CNC laser cutting service, but don’t know where to turn. You’ve probably heard horror stories about services that missed deadlines, delivered poor-quality products, or simply couldn’t be counted on. Don’t worry; ABT Metals is always here to help.

We’re not like the other guys. We’re a family-owned business with over 25 years of hands-on experience providing metal laser-cutting services to a broad spectrum of industries. Our advanced technology, exacting standards, and responsive customer care consistently exceed expectations. We deliver the speed, precision, and professionalism you demand—on time, every time.

What is CNC Laser Cutting?

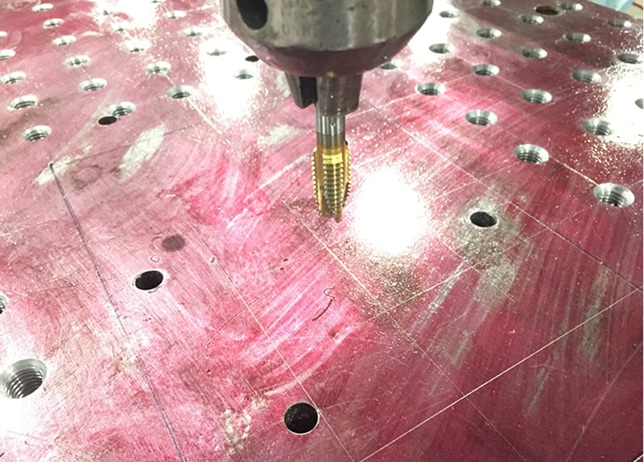

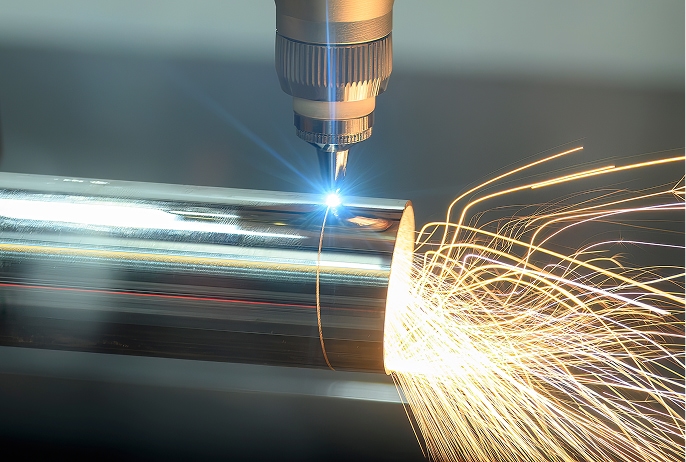

Custom CNC laser cutting is a computer-controlled metalworking process that utilizes a high-powered laser to cut flat, rigid materials like metals and plastics. This technology allows for incredibly precise and accurate cuts, making it ideal for applications that demand precision and tight tolerances.

Our State-of-the-Art CNC Fiber Optic Laser Cutting Technology

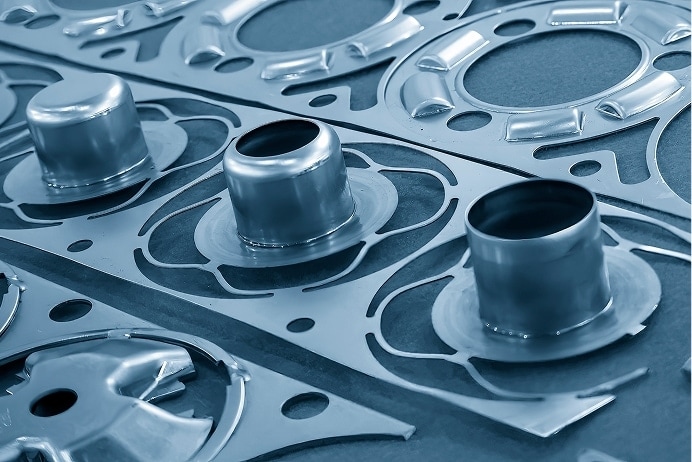

Our custom CNC metal cutting services utilize industry-leading fiber optic lasers—the all-solid-state HDF series—to achieve highly intricate, clean, and precise cuts. Fiber optic technology surpasses traditional CO₂ lasers by effortlessly handling “brown” and highly reflective metals previously considered challenging.

With bed sizes reaching 80” x 160”, our lasers accommodate sizable sheet metal projects without compromising accuracy. We consistently cut mild steel up to 1 inch thick, and aluminum and stainless steel up to 7/16 inch thick, empowering you with unparalleled precision and flexibility.

Advantages of CNC Laser Cutting

- Precision: Achieve high tolerances with accurate cuts.

- Speed: Cut materials faster and efficiently.

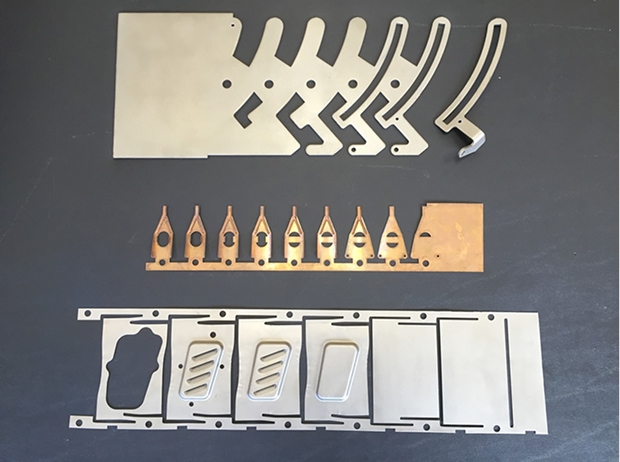

- Versatility: Create any desired shape or design.

- Cost-effective: Save money by reducing waste material.

How Does CNC Laser Cutting Work?

CNC laser cutting focuses a high-powered laser beam on the material to be cut, melting or vaporizing it to achieve the desired shape or design. The process is controlled by a computer, ensuring precision and accuracy.

Steps in a CNC Laser Cutting Process

- Setup: Prepare the machine and material.

- Cutting: Focus the laser beam onto the material along the cutting path.

- Finishing: Remove any debris post-cutting.

- Cleaning: Clean the machine and bed for future use.

Applications for CNC Laser Cutting

Our expert laser cutting and sheet metal services cater to industries demanding precision, reliability, and efficiency. Common applications include:

- Automotive & Aerospace Components: Custom car parts or mass production components and aircraft parts manufacturing.

- Electronic & Technology Enclosures: Custom circuit boards creation.

- Precision Medical Equipment: Medical device fabrication.

- Decorative Metalwork & Signage: Versatile applications in arts and crafts.

Certified Precision Laser Cutting Services, Verified Quality

We’re not just another metal laser-cutting company. ABT Metals Manufacturing proudly operates under strict ISO 9001:2015 certification. This internationally recognized certification underscores our unwavering commitment to consistent quality, traceable processes, and continuous improvement—exactly the level of accountability your project deserves.

Whether you need mass-produced components or intricate custom metal laser cutting solutions, ABT Metals Manufacturing is your ideal partner. Our experienced engineers can help you develop, design, and manufacture the metal parts you need efficiently. Contact us for a production quote tailored to your requirements.

Why ABT Metals Beats the Competition, Cut for Cut

Why choose us among metal laser cutting companies in North Carolina and beyond? Here’s how we deliver exceptional value:

- Uncompromising Precision: Advanced fiber optic laser cutting ensures unmatched accuracy and quality.

- Reduced Waste & Cost: Expert material nesting optimizes material use, minimizing scrap and lowering your production costs.

- Rapid Turnaround: Advanced CNC metal laser cutting technology accelerates lead times, meeting demanding schedules without sacrificing accuracy.

- Dedicated Engineering Support: In-house engineers optimize your production methods to streamline processes and enhance overall efficiency.

- Customer-Centric Communication: We’re responsive, transparent, and proactive, providing updates every step of the way.

Metal Laser Cutting Service

Leverage our state-of-the-art CNC laser cutting machinery for accurate cuts in metal. We utilize advanced laser equipment that allows for precise and efficient production of metal parts.

Materials & Alloys We Specialize In

Our specialized alloy laser cutting services include diverse materials that ensure optimal outcomes for your unique requirements. Common materials we expertly handle:

- Aluminum (also known as Alloy 5052, 6061)

- Stainless Steel (304, 316 series alloys)

- Mild Steel (also called Carbon Steel)

- Brass (often called Copper-Zinc Alloy)

Each alloy’s characteristics—like strength, ductility, and reflectivity—impact cutting performance. We help you select the ideal metal and approach to achieve your design, performance, and budget objectives.

Exact Isn’t an Option—It’s Our Standard

ABT Metals maintains industry-leading tolerances through rigorous calibration and advanced programming methods. Our sheet metal laser cutting services consistently achieve accuracy within ±0.005 inches, even with complex contours and tight specifications, ensuring each component precisely fits your design vision.

Ready for Precision? Request Your Free Quote Today

Experience precision metal fabrication at its best with ABT Metals Manufacturing. Whether you’re looking for high-volume production or intricate prototypes, our seasoned team has the expertise, technology, and dedication you can rely on.

Request A Quote today and discover why customers across industries choose ABT Metals as their preferred metal laser-cutting manufacturer in North Carolina and beyond.

Additional Services We Offer

At ABT Metals Manufacturing, we take pride in offering the highest quality metal fabrication services in North Carolina.

Frequently Asked Questions

What is a fiber optic laser?

Fiber optic lasers, like our HDF series, are all-solid-state systems that efficiently cut challenging “brown” and highly reflective metals previously problematic for traditional CO₂ lasers. These fiber lasers provide superior speed, accuracy, and efficiency, with the capability to process mild steel up to 1” thick, and stainless steel and aluminum up to 7/16” thick, all within an expansive bed size of 80” x 160”.

What type of metal is CNC laser cutting suited for?

Several metals, including aluminum, stainless steel, mild steel, and brass, are ideal for CNC laser cutting. The choice of metal directly influences your finished product’s precision, turnaround time, and overall quality. For instance, aluminum offers rapid cutting and efficient turnaround, while brass typically requires additional time and care due to its challenging cutting properties.

Give us a call or fill out the form and our team will be in touch as soon as possible.

*marks a required field

Quick Contact

"*" indicates required fields